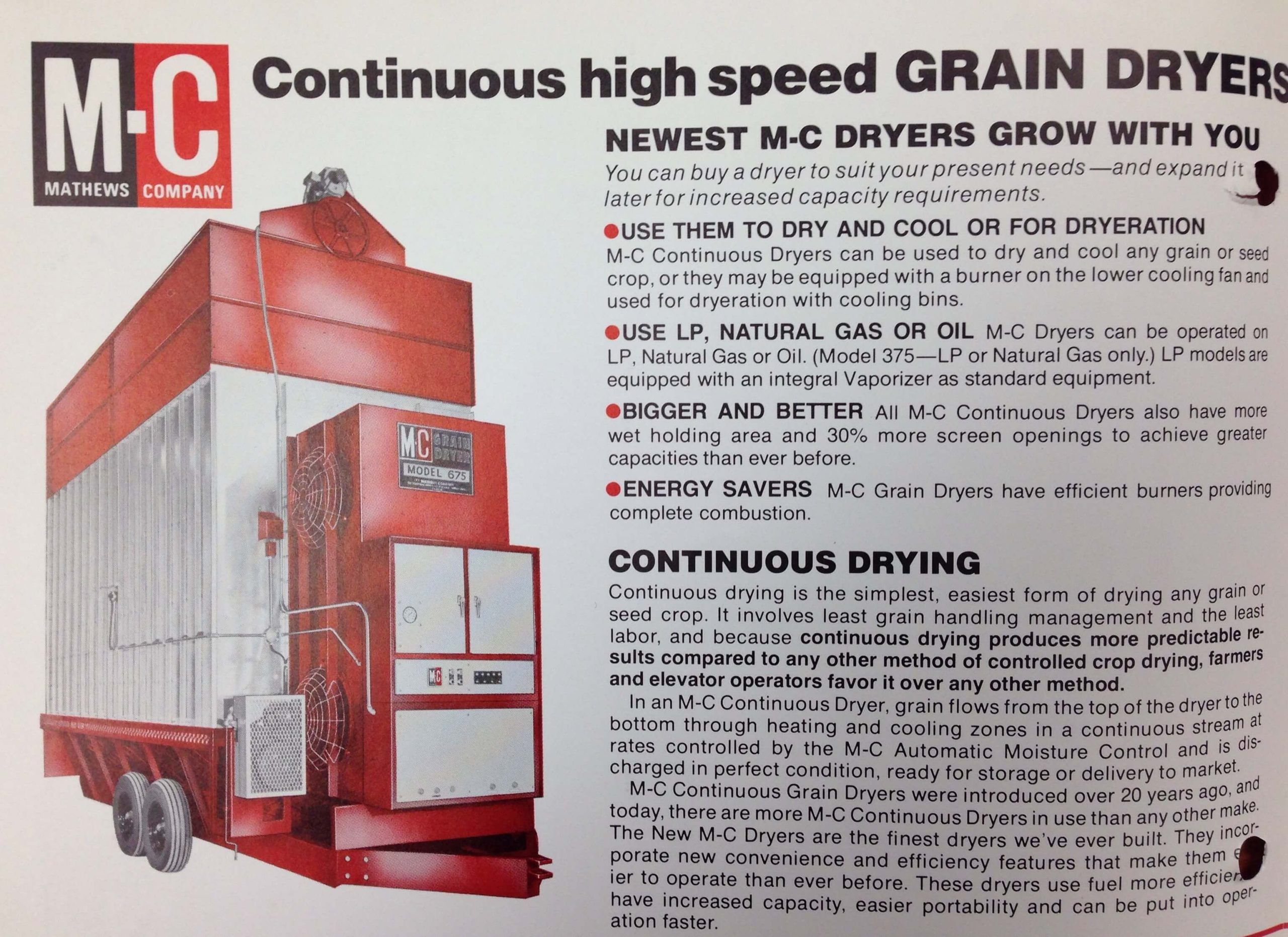

History of

Mathews Company

For over 70 years, MC has been dedicated to building equipment that farmers can trust—designed with engineering excellence and built to last with Iron Horse Quality. From pioneering grain dryer technology to expanding into complete grain site solutions, our history reflects a balance of tradition and innovation. Every milestone represents our commitment to dealers, customers, and the agricultural community we serve.

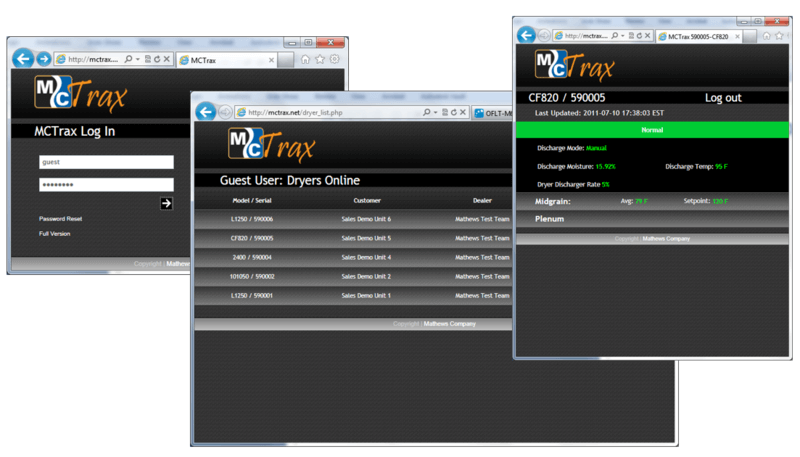

MC Trax Overhaul Unveiled

Building on the success of its original 2011 release, MC introduced a major overhaul of the MC Trax remote monitoring and control system in 2024. The update delivered a completely redesigned user interface optimized for mobile, tablet, and desktop, along with a new multi-dryer view for managing several units simultaneously. Backed by Amazon Web Services (AWS) cloud hosting, the platform gained faster performance, higher uptime, and enhanced data security. Other improvements included smarter, targeted alert notifications, light/dark mode display options, and an intuitive overview screen that made real-time monitoring easier than ever. This overhaul marked a leap forward in reliability and usability, reinforcing MC Trax as a dealer and customer favorite during harvest season.

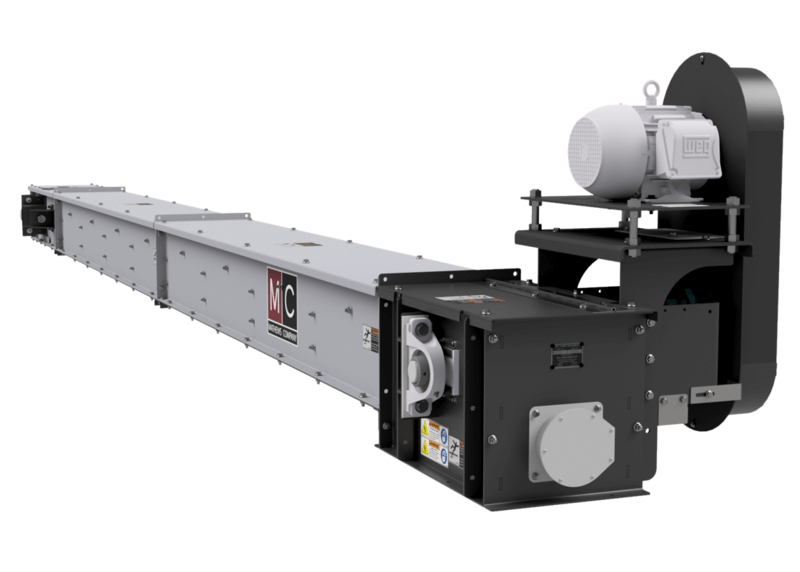

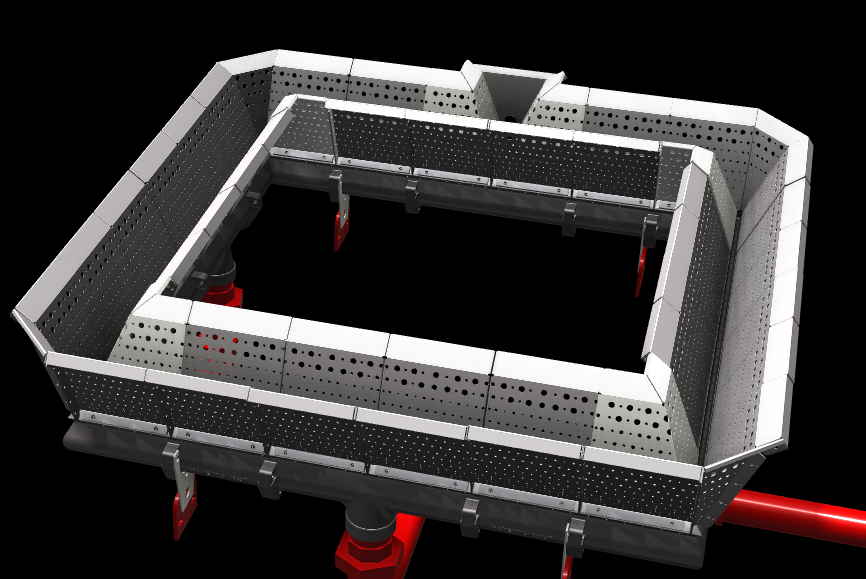

Drag Conveyors Introduced

MC expanded further into material handling with the launch of its drag conveyor product line. Built with heavy-duty galvanized construction and abrasion-resistant materials, these conveyors were engineered for long-term reliability and durability. Designed to deliver capacities exceeding 10,000 bushels per hour, they offered a wide range of trough sizes and chain speeds to suit diverse applications. Modular lengths, incline configurations, and premium drive components provided dealers and end-users with flexible solutions tailored to their site layouts. With this addition, MC strengthened its position as a full grain site specialist, delivering integrated handling and drying systems backed by Iron Horse Quality.

70th Anniversary & New MC Branding Introduced

In 2024, MC proudly celebrated its 70th year in business, marking seven decades of innovation, quality, and service to the agricultural industry. To commemorate this milestone, the company unveiled a new logo and updated branding that honored its past while presenting a sleek, modern identity. The refreshed design retained MC’s signature red and block-letter inspiration, symbolizing the company’s Iron Horse quality and ongoing commitment to continuous improvement. The rollout included updated brochures, decals, websites, trade show displays, and more, reinforcing MC’s position as a trusted, forward-looking leader in grain site solutions.

Bucket Elevator Product Line Introduced

Continuing its expansion into material-handling solutions, MC launched its line of bucket elevators in 2023. Engineered with heavy-duty galvanized trunking, solid welded head sections, and premium drive components, these elevators were designed for durability and reliable high-capacity performance. Options such as service and distributor platforms, modular ladder and cage systems, and vented head sections provided safe access and improved site integration. With discharge capacities ranging from 1,300 to over 13,000 bushels per hour, MC’s bucket elevators offered dealers and customers a robust and versatile complement to grain dryers.

Grain Distributor Product Line Introduced

MC expanded beyond dryers for the first time with the launch of its grain distributor product line, marking the company’s entry into complementary material-handling solutions. Built with solid welded construction and available in multiple port configurations, these distributors featured options such as maintenance platforms, blower mounts, and durable galvanized or powder coat finishes. With easy access doors and customizable liners, the product line was engineered for long service life and adaptability to diverse grain site layouts. This milestone signaled MC’s broader commitment to becoming a full grain site specialist, offering dealers and customers integrated solutions that extend beyond drying equipment.

Fusion Series Mixed-Flow Dryer Introduced

Following the success of the Delta Series, MC expanded its presence in the mixed-flow segment with the introduction of the Fusion Series. Built on the same SmartFlow™ tapered duct technology that delivers superior grain quality and efficiency, Fusion added new advantages including flexible drying options with independently controlled plenums, quieter operation with double-inlet centrifugal fans, and an expandable modular design for future growth. Equipped with Pinnacle 20|20 controls, MC Trax remote monitoring, and optional AccuDry™ automation, Fusion gave customers more flexibility and scalability than ever before. Together, the Delta and Fusion further solidified MC as a leader in mixed-flow technology, with Fusion serving as the versatile counterpart to Delta’s high-capacity performance.

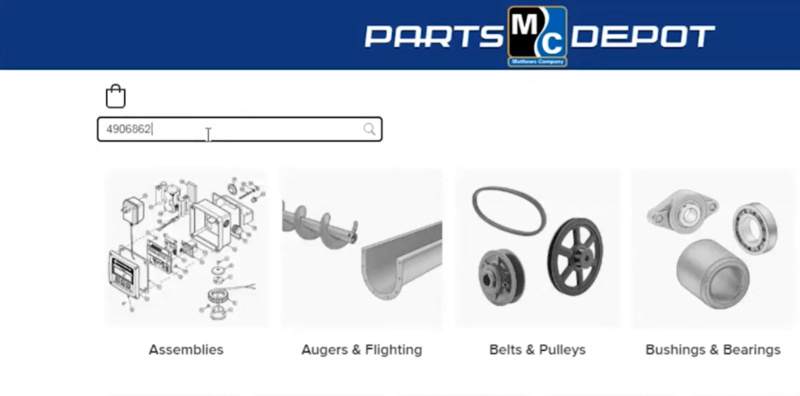

Parts Depot Online Ordering System Introduced

MC expanded its digital support offerings for dealers with the launch of Parts Depot, a 24/7 online platform for ordering replacement parts. Designed with real-time availability, and intuitive navigation, Parts Depot gave dealers quick, reliable access to the parts they needed anytime, anywhere. By minimizing downtime and simplifying the replacement process, this innovation strengthened MC’s commitment to keeping operations running smoothly during the most critical times of the season.

MC Tech Chat Unveiled for Dealer Support

In 2019, MC launched MC Tech Chat, a dealer-exclusive support platform designed to deliver fast, reliable assistance during peak harvest. Built as a modern chat-based tool, it gave dealers direct access to MC’s technical team for quick troubleshooting, setup guidance, and operational questions. By streamlining communication and reducing downtime in the field, MC Tech Chat reinforced the company’s commitment to supporting its dealer network with innovative solutions that matched the urgency of harvest season.

Delta Series Mixed-Flow Dryer Unveiled

MC entered the mixed-flow drying market with the introduction of the Delta Series, one of the most significant product launches in company history. Featuring MC’s exclusive SmartFlow™ tapered duct design, the Delta Series combined the fuel efficiency and grain quality advantages of mixed-flow drying with MC’s proven engineering and control systems. Standard equipment included Pinnacle 20|20 touchscreen controls, optional AccuDry™ moisture-based automation, and full integration with MC Trax remote monitoring. The series offered high capacities, quieter operation with commercial-grade in-line centrifugal fans, and consistently superior grain quality. Quickly embraced by dealers and customers, the Delta Series remains one of MC’s most popular and best-performing dryers, establishing MC as a leader in the mixed-flow segment.

Next Generation Legacy Series Introduced

MC unveiled the Next Generation Legacy Series, a complete redesign of one of its most established product lines. Developed in partnership with the Propane Education & Research Council (PERC), the project applied proven tower and ECO Series technology to a “profile” style dryer, delivering vacuum-cool efficiency, improved airflow, and more reliable capacities. Featuring in-line centrifugal fans, proprietary burner technology, and the Pinnacle 20|20 control integration, the series provided energy savings, quieter operation, and consistently high grain quality. This launch modernized the Legacy line while reinforcing propane’s role in on-farm grain drying and expanding MC’s reputation for innovative, efficient solutions.

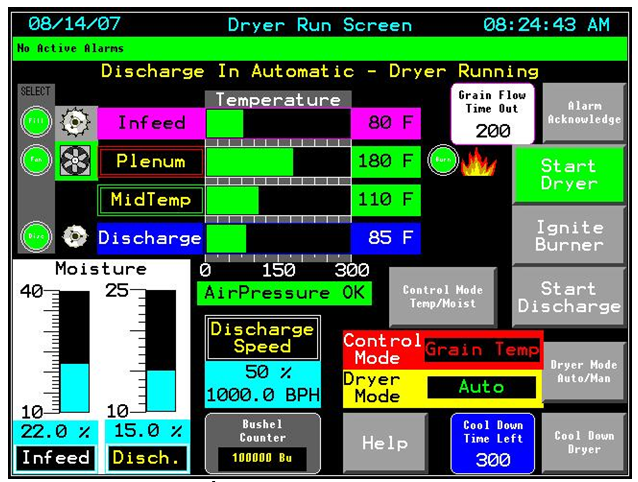

Pinnacle 20|20 Unveiled

MC took a major leap forward in dryer automation with the launch of the Pinnacle 20|20 control system, the next generation of its Pinnacle family. Designed around dual 10-inch high-definition touchscreens, Pinnacle 20|20 provided operators with an intuitive graphical interface, real-time trending of moisture and temperature data, and robust diagnostic tools all within two touches of the home screen. By replacing physical buttons and switches with a fully touchscreen-driven PLC platform, the system simplified navigation, improved safety with a 24 VDC control circuit, and enhanced serviceability with on-screen fault assistance and component resource libraries. Compatible across all MC’s dryers, Pinnacle 20|20 redefined ease of use while delivering deeper operational insight and reliability. It marked a new era of smart drying technology, setting the standard for precision, connectivity, and customer confidence.

ECO Series Introduced

In 2015, MC introduced the ECO Series, a new generation of low-profile dryers designed to replace the Infinity Series and overcome its performance limitations. Developed in collaboration with the Dealer Advisory Council, the ECO Series was engineered for both value and efficiency, giving customers a competitively priced solution without compromising MC’s standards of quality. Available in 12’, 16’, 20’, and 24’ lengths, ECO dryers featured a 14” grain column, high-efficiency burners, and a single centrifugal fan design that delivered reliable airflow and fuel efficiency. Standard equipment included digital plenum temperature control, Pinnacle Lite touchscreen operation, TruDry discharge control, and compatibility with AccuDry™ moisture-based automation and M-C Trax remote monitoring. Building on the success of the initial lineup, MC later added a 28’ model to meet customer demand for greater capacity. The ECO Series quickly earned recognition as a practical, cost-effective drying solution for farms of all sizes, cementing its place as the successor to Infinity.

Re-Designed 12’ Tower Dryer

Building on the success of the re-engineered 10’ tower dryer a year earlier, MC applied the same advanced design methodology to its 12’ tower series, creating the 2nd Generation 12’ Tower. The redesign introduced new model options (12-20-100, 12-24-125, and 12-28-150) and delivered enhanced airflow, improved burner efficiency, and the integration of Pinnacle controls, AccuDry™ moisture-based automation, and MC Trax remote monitoring. Configurable modular grain exchangers were added as an option for increased flexibility, while refinements to screen perforation design improved drying consistency and reduced external buildup. The modular construction also streamlined installation, significantly reducing on-site assembly time and labor costs. Limited prototype installations in 2014 validated the new design under real-world harvest conditions. This next-generation 12’ tower reinforced MC’s leadership in delivering high-capacity drying solutions with smarter technology, modularity, and superior grain quality outcomes.

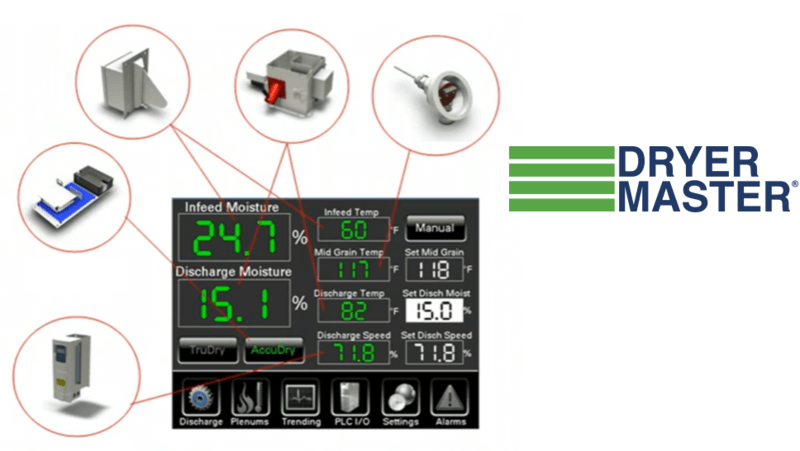

Re-Designed 10’ Tower Dryer

MC unveiled a completely re-engineered 10’ tower dryer in 2013, setting a new benchmark for efficiency, accuracy, and operator convenience in the on-farm grain drying market. The redesign incorporated a commercial-grade centrifugal blower for certified airflow, a high-efficiency low-emissions burner, and AccuDry™ moisture-based controls powered by Dryer Master for unmatched precision in final grain moisture. Operators benefited from the Pinnacle Lite or full Pinnacle touchscreen system with trend data and alarms, while MC Trax enabled remote monitoring from smartphones, tablets, or computers. Additional enhancements, including digital plenum temperature control, ensured consistent drying temperatures and optimal fuel efficiency. This new generation of 10’ tower dryers reinforced MC’s position as an innovator by combining commercial-grade performance with cutting-edge automation and connectivity.

Exclusive Partnership with Dryer Master – AccuDry™ Control System

In 2012, MC announced an exclusive partnership with Dryer Master to bring advanced moisture-based drying control directly into its product line. This collaboration introduced the AccuDry™ control system, powered by Dryer Master’s proven real-time moisture monitoring technology. By measuring both incoming and discharged grain moisture, AccuDry automatically adjusted the dryer’s discharge rate to deliver precise and uniform results. The embedded DM510 solution was seamlessly integrated into MC’s Pinnacle and Pinnacle Lite control system, giving operators a customized interface with powerful behind-the-scenes intelligence. With this innovation, MC customers gained a higher level of accuracy, consistency, and efficiency in their drying process, strengthening MC’s reputation for delivering cutting-edge solutions tailored to the evolving needs of modern grain operations.

MC Trax Remote Monitoring

MC broke new ground in grain dryer technology with the launch of MC Trax, one of the industry’s first smartphone-based remote monitoring applications. MC Trax gave farmers unprecedented oversight of their drying operation from anywhere in the world. Users could view real-time moisture and temperature readings, receive instant SMS alerts for critical alarms and review historical performance trends. This innovation not only improved convenience and efficiency but also gave operators greater peace of mind during the busy harvest season. Over time, MC Trax evolved into a fully cross-platform solution available on both Apple and Android devices, becoming a cornerstone of MC’s connected technology strategy.

Introduction of the Pinnacle Family of Control Systems

MC launched its Pinnacle family of dryer control systems with the debut of the Pinnacle Lite featuring TruDry™ technology. This was the company’s aggressive step into touchscreen-based, PLC-driven controls, providing operators with precise moisture management, automatic discharge rate control, and real-time monitoring capabilities on all machines as it’s standard offering. The system combined state-of-the-art RTD sensors, Ethernet connectivity for remote access, and a user-friendly interface, setting a new standard in grain dryer automation. With Pinnacle, MC moved beyond traditional manual controls to deliver a smarter, more accurate, and more reliable drying experience, reinforcing its reputation as a leader in innovation.

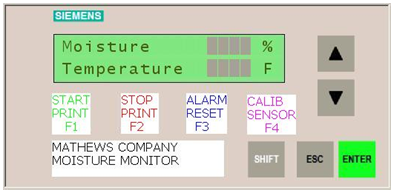

Real-Time Dryer Monitoring

Mathews Company enhanced operator experience and dryer performance with the introduction of Siemens-based two-line touch controls, giving users real-time access to critical data like grain moisture and temperature. These intuitive displays made it easier to monitor and adjust dryer settings on the fly, improving drying consistency and reducing the risk of grain spoilage. The advanced touch interface also simplified diagnostics and maintenance, empowering farmers with better control over their drying process. This milestone reflected MC’s commitment to integrating cutting-edge technology for smarter, more efficient grain management.

Introduction of the 18’ Tower Dryer

Mathews Company reached new heights with the debut of its 18-foot tower dryer, the largest and most powerful grain dryer in the company’s history. Engineered for industrial-scale grain operations, these tower dryers delivered exceptional capacity, efficiency, and drying precision to meet the demands of the largest farms and commercial grain facilities. Featuring advanced airflow and heat control systems, the 18-foot towers offered faster drying times and improved grain quality, even at massive volumes. This milestone demonstrated MC’s commitment to pushing boundaries and supporting customers as agricultural operations grew bigger and more complex.

Debut of the Infinity Series

Mathews Company introduced the Infinity Series, a groundbreaking grain dryer line designed to deliver unmatched performance, energy efficiency, and dependability. Engineered with advanced airflow dynamics and enhanced heat distribution, these dryers offered faster, more uniform drying while reducing fuel costs. Farmers quickly embraced the Infinity Series for its consistent results, durable construction, and user-friendly operation, making it a standout in MC’s product lineup. This milestone cemented the Infinity Series as a go-to choice for small-operation growers seeking reliable, high-capacity drying solutions season after season.

Automatic Fuel Controls

Mathews Company took a major step forward in safety and efficiency with the introduction of automated burner temperature controls, featuring digital valves integrated into the fuel train. This innovation allowed precise, real-time adjustments to burner operation, maintaining consistent drying temperatures while reducing fuel consumption and operator intervention. By automating critical fuel system functions, MC enhanced both performance and peace of mind for farmers, setting a new standard for modern grain dryer controls. This milestone reinforced MC’s commitment to leveraging technology for smarter, safer drying solutions.

PLC “Smart Controls”

Mathews Company ushered in a new era of precision and automation with the launch of its first PLC-based smart controls, utilizing Red Lion HMI and Siemens PLC systems to give operators unparalleled control over their dryers. These intelligent controls allowed farmers to monitor temperatures, adjust discharge rates, and automate processes for more consistent drying and reduced the risk of over drying or spoilage. By integrating advanced sensors and a user-friendly interface, MC’s smart controls dramatically improved efficiency, safety, and ease of operation. This milestone marked a significant technological leap that set the stage for future innovations in grain dryer automation.

12’ Tower Dryer Debut

MC took a major step into the commercial grain drying market with the introduction of its first 12-foot tower dryer, engineered for large-scale operations requiring higher capacities and efficiency. These commercial-grade towers delivered faster drying speeds, improved airflow, and robust construction to handle the demands of modern grain facilities. By expanding beyond the 10-foot design, MC provided customers with versatile options tailored to both family farms and large commercial elevators. This milestone underscored MC’s commitment to meeting the needs of a growing agricultural industry with innovative, high-capacity solutions.

First 10’ Tower Dryer Design

Building on the knowledge and experience gained from acquiring the Kan-Sun tower dryer line in 1989, Mathews Company released its first fully in-house designed 10-foot tower dryer with models 10420 through 10750. These new tower dryers integrated years of customer feedback and engineering advancements, featuring optimized airflow, improved heat distribution, and enhanced safety systems. By designing the towers entirely in-house, MC took full control of quality and innovation, ensuring these dryers met the evolving demands of modern farming. This milestone marked a significant evolution from the Kan-Sun foundation to a new era of MC-engineered solutions that set a higher standard for performance and reliability.

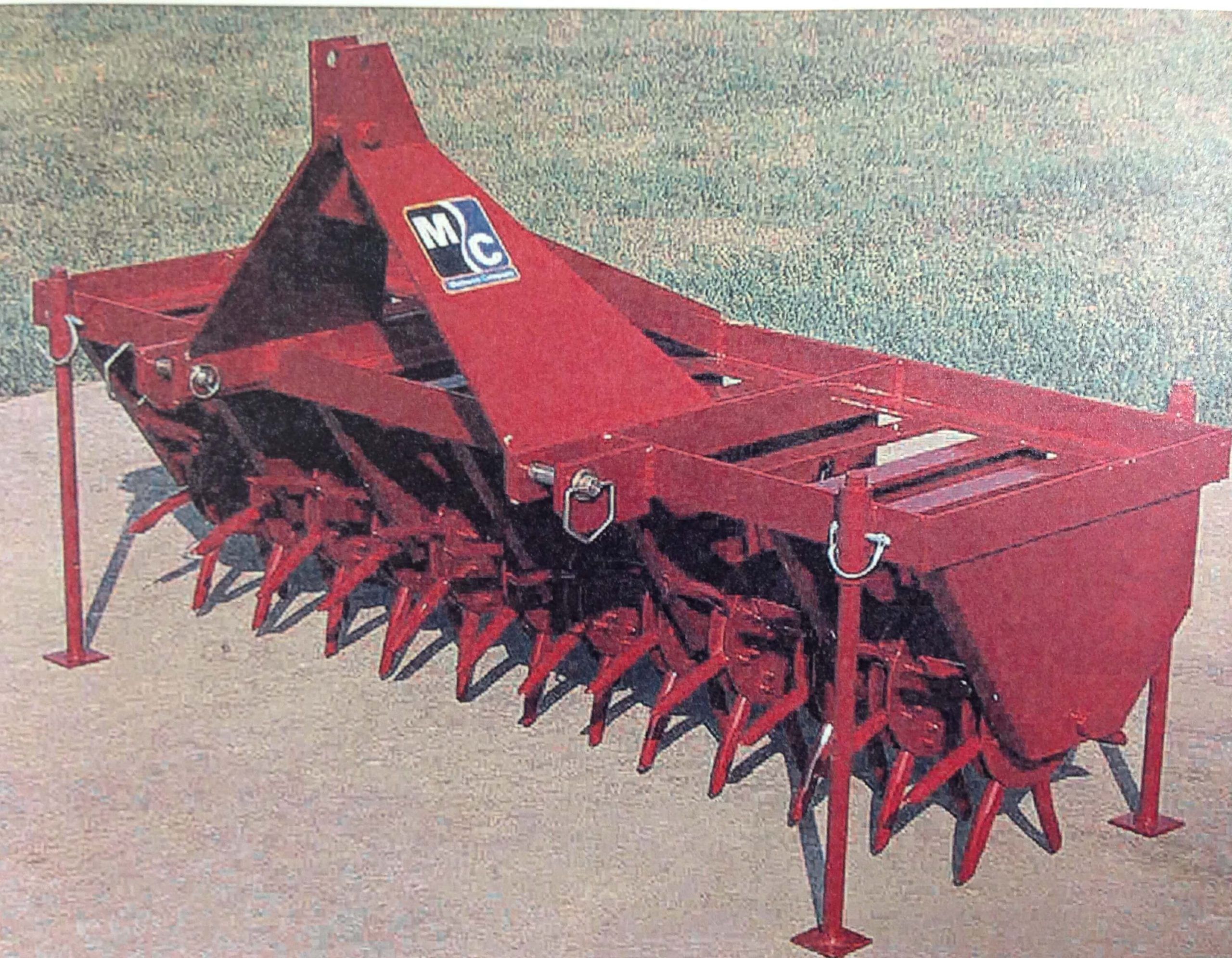

Aerators

Mathews Company introduced its line of heavy-duty aerator systems, purpose-built for total ground relief in turf, pasture, and soil conditioning applications. These rugged aerators penetrated deeply to break up compacted soil, improving water infiltration, root growth, and overall soil health. Designed for durability and ease of use, MC Aerators quickly became an essential tool for farmers, landscapers, and groundskeepers aiming to revitalize their land. This milestone reflected MC’s ongoing commitment to engineering solutions that help customers get the most from every acre.

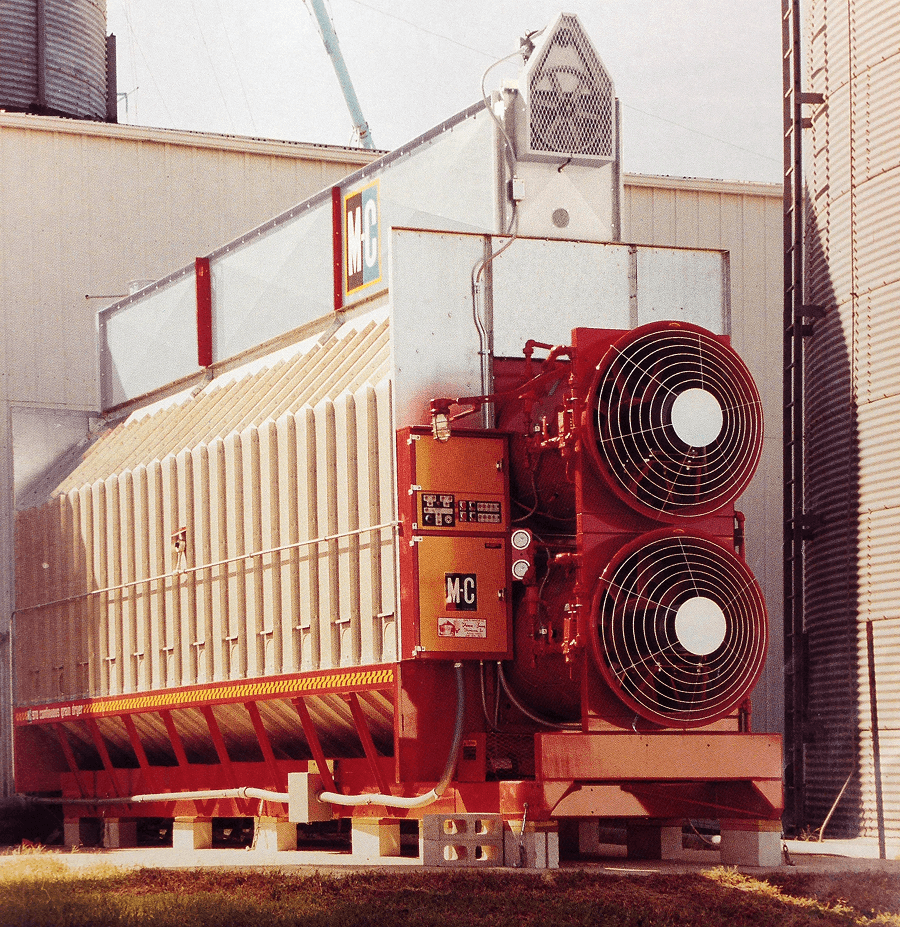

80 Series Debut

MC introduced the advanced 80 Series grain dryers, raising the bar for drying efficiency, capacity, and control. These dryers featured state-of-the-art airflow and heat distribution systems, enabling faster and more uniform moisture removal while preserving grain quality. With enhanced automation options and robust construction, the 80 Series provided farmers with dependable, high-performance drying solutions that could handle larger harvests with ease. This milestone solidified MC’s reputation for innovation and its dedication to helping growers achieve better results every season.

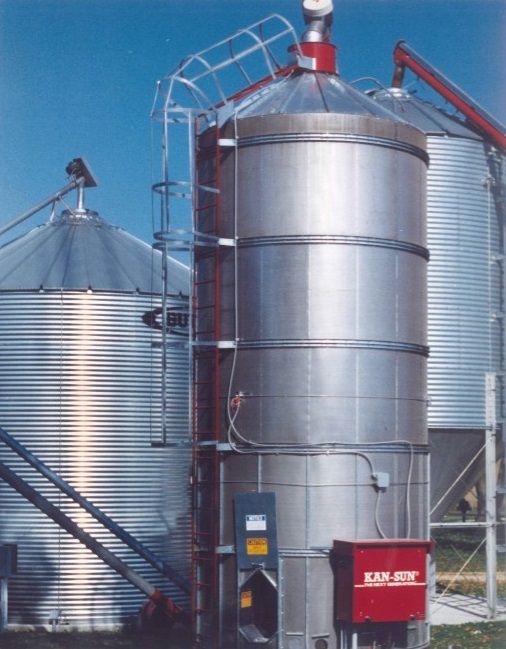

Kan-Sun Acquired

Mathews Company expanded its product portfolio by acquiring the Kan-Sun tower dryer line, enhancing its lineup of continuous flow grain dryers. The addition of Kan-Sun’s proven design provided farmers with a high-capacity, energy-efficient solution for large-scale drying needs. By integrating this trusted brand, MC offered even more options tailored to different farm operations, reinforcing its leadership in grain drying technology. This strategic acquisition marked a major step forward in MC’s commitment to delivering comprehensive, innovative drying systems to growers worldwide.

Pulverizers

MC set a new benchmark in soil preparation with the launch of its “Big Tooth” pulverizers, engineered with double roller durability to handle the toughest ground conditions. These rugged machines broke up clods and smoothed soil with unmatched efficiency, making them ideal for everything from seedbed preparation to landscaping projects. Farmers and contractors appreciated their reliable performance and ability to create a perfectly graded surface, reducing the need for additional passes. This milestone showcased MC’s commitment to designing tools that delivered superior results and stood up to demanding work.

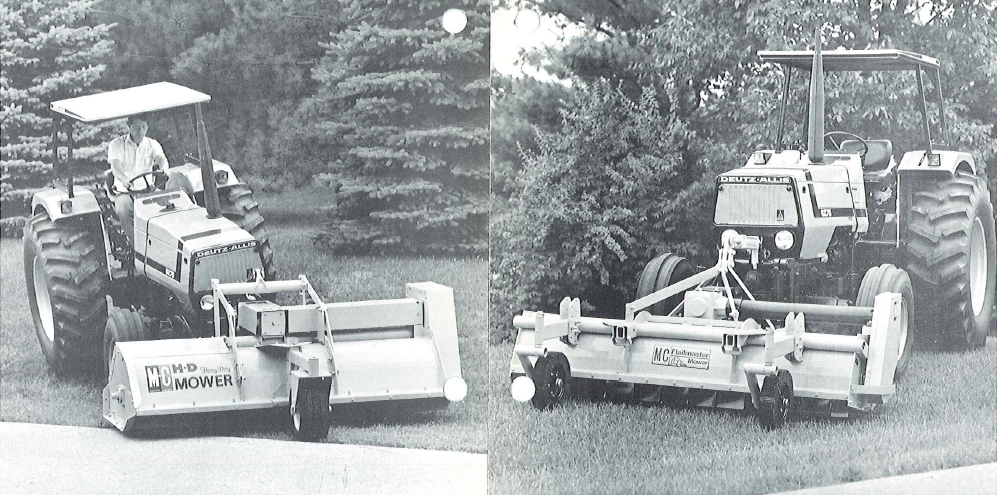

Flail Mowers

Mathews Company solidified its reputation for rugged, reliable equipment with its line of heavy-duty flail mowers, designed to tackle the toughest mowing challenges with ease. Built for exceptional durability, these mowers provided consistent, fine cuts through thick grass, brush, and crop residue, making them a favorite for farmers and groundskeepers alike. Their robust construction minimized downtime and maintenance, ensuring long-lasting performance season after season. This milestone highlighted MC’s dedication to producing equipment that combined power, efficiency, and user-friendly operation.

70 Series Debut

Mathews Company advanced its legacy of grain drying innovation with the release of the 70 Series grain dryers, designed to deliver even greater efficiency and reliability. Featuring enhanced airflow systems and upgraded burner technology, these dryers offered faster, more uniform drying to protect grain quality and boost throughput. The distinctive profile design not only improved performance but also simplified maintenance, making the 70 Series a favorite among farmers looking for dependable equipment. This milestone reinforced MC’s position as a pioneer in modern grain drying solutions.

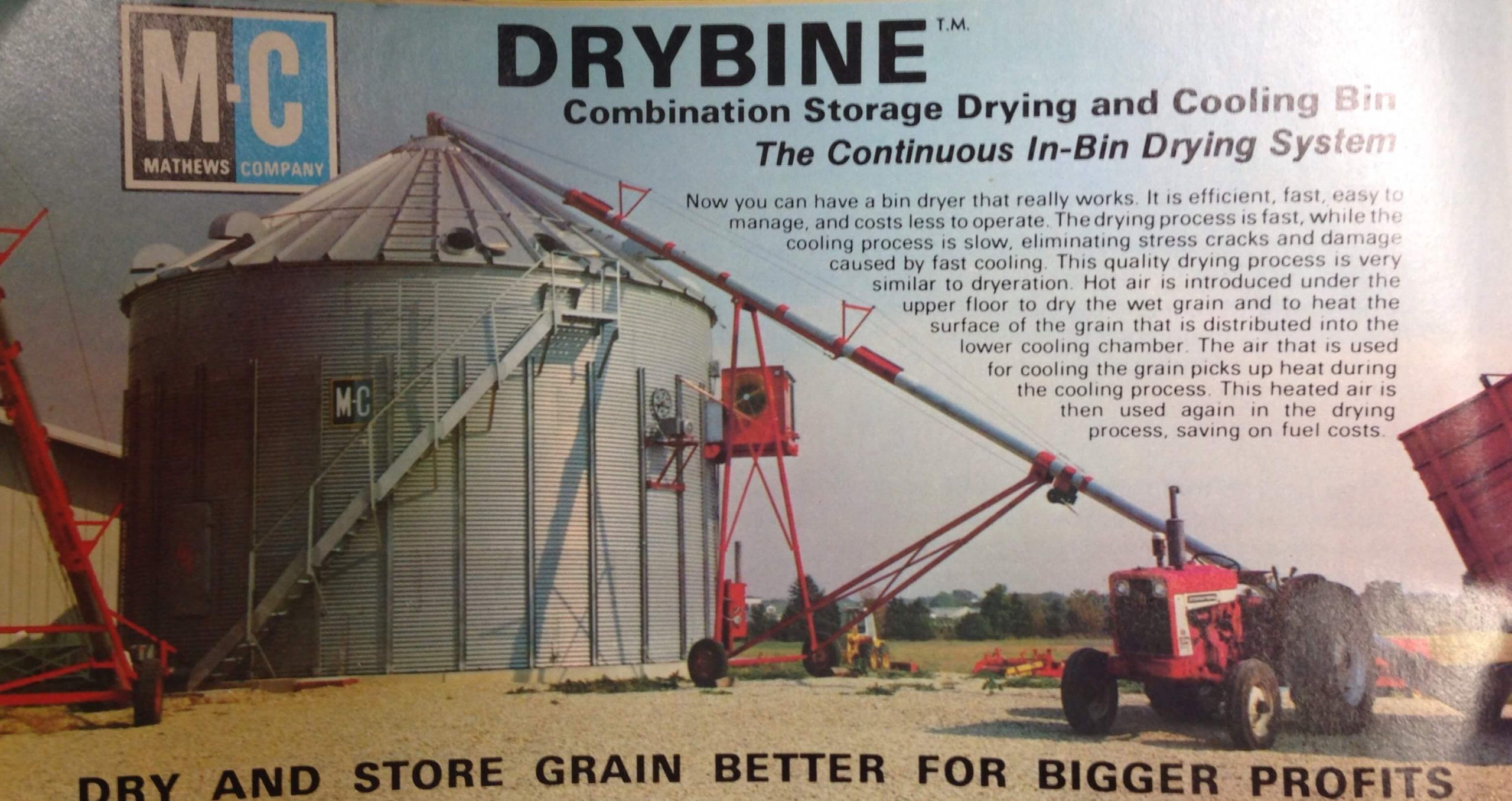

Drybine

MC revolutionized on-farm grain management with the introduction of the Drybine, a complete in-bin drying system combining storage, drying, and cooling in a single unit. Featuring an integrated MC burner and strategically positioned mid-bin fan, the Drybine offered farmers greater control over moisture levels while maximizing energy efficiency. This innovative design streamlined the drying process, reduced grain handling, and minimized spoilage risk, all while saving on fuel costs. The Drybine quickly became a trusted solution for growers looking to protect and preserve their harvest with less hassle.

Flex Shredders

Mathews Company launched its innovative Flex Shredders, featuring collapsible-span designs with cutting widths of 24 and 30 feet, revolutionizing residue management for large-scale farming operations. These flexible shredders made it easier for farmers to efficiently cover wide fields while still navigating tight turns and transport routes. The robust construction and adaptable folding wings allowed quick transition from fieldwork to road travel, saving time and labor. This milestone demonstrated MC’s commitment to engineering versatile equipment that matched the evolving demands of modern agriculture.

Bin Fans

MC introduced its first line of stand-alone bin fans, designed specifically for in-bin grain drying and aeration, providing farmers with more control over moisture levels and storage conditions. These durable, high-performance fans improved airflow through grain bins, helping to preserve grain quality and reduce spoilage risks. With easy installation and reliable operation, MC bin fans quickly became an essential tool for farmers looking to extend storage life and protect their harvests. This milestone reinforced MC’s dedication to delivering practical solutions that meet real-world farming needs.

75 Series Debut

Mathews Company launched the groundbreaking 75 Series of low profile grain dryers, designed to deliver faster, more efficient drying with improved grain quality. These advanced dryers featured increased air flow and expanded screen areas, enhancing capacity and consistency to meet the evolving needs of modern farmers. With versatile fuel options and modular configurations, the 75 Series set a new benchmark for flexibility and performance in grain drying technology. This milestone solidified MC’s reputation as a leader in innovative solutions that help farmers maximize their harvests.

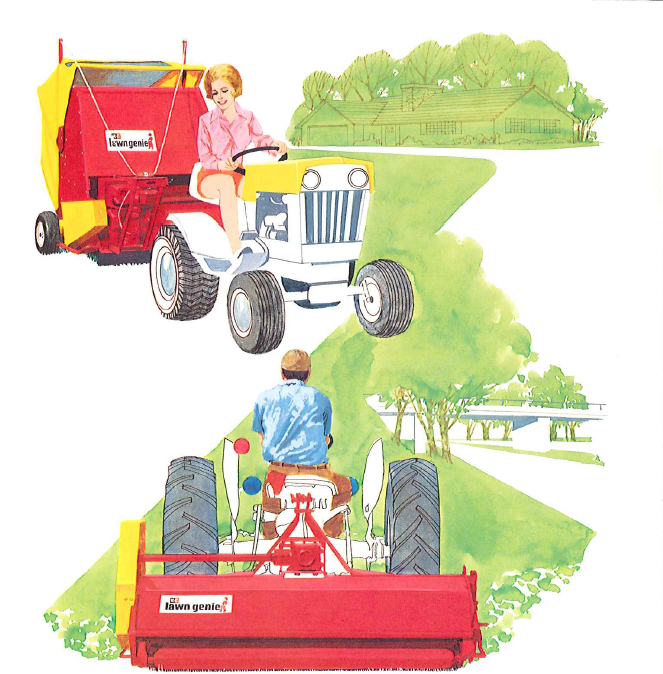

Lawn Genie

Mathews Company unveiled the Lawn Genie, the first flail mower in its lineup designed to collect freshly cut grass into a rear-mounted hopper, simplifying lawn care for homeowners and professionals alike. This innovative design reduced the need for raking or bagging, saving time while delivering a clean, polished look to large lawns and estates. The Lawn Genie combined MC’s rugged engineering with user-friendly operation, expanding the company’s reach beyond farms and into residential and commercial landscaping. This milestone showcased MC’s versatility and commitment to making outdoor maintenance easier for everyone.

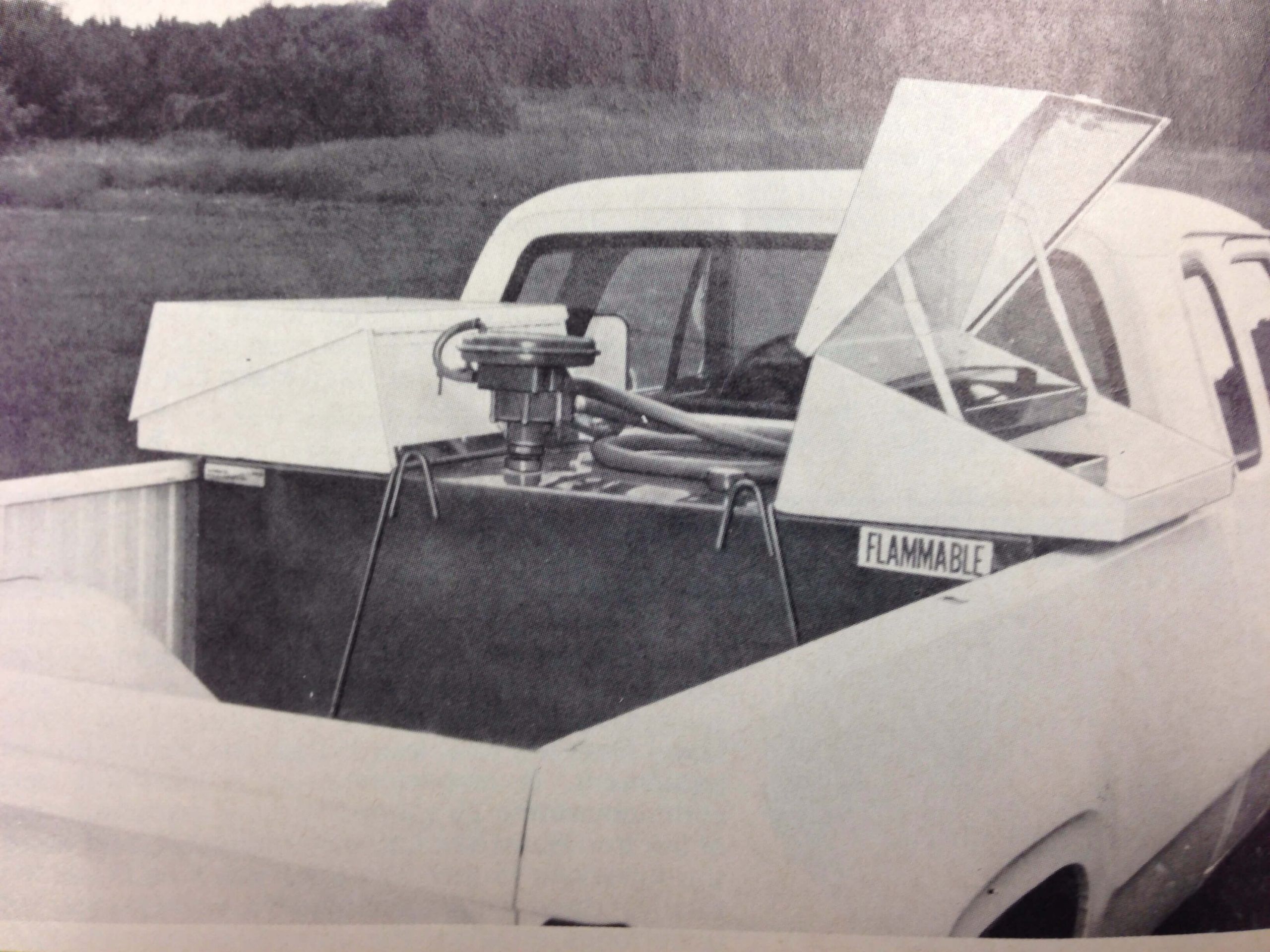

Fuel Tanks

MC introduced innovative portable fuel tanks designed to fit standard truck beds, transforming ordinary pickups into mobile refueling stations. These rugged tanks gave farmers and contractors the flexibility to carry and dispense fuel directly to equipment in the field, saving valuable time and reducing downtime. Built with safety and convenience in mind, MC’s fuel tanks featured secure compartments and easy-access hoses, quickly becoming an indispensable tool on farms and worksites. This milestone showcased MC’s knack for practical solutions that kept operations running smoothly.

MC Combines

Mathews Company ventured into new territory by developing two prototype combines, showcasing its innovative spirit and commitment to exploring cutting-edge solutions for farmers. These machines were designed to offer superior harvesting performance and operator comfort, reflecting MC’s dedication to improving every step of the farming process. One of the original prototypes still proudly resides on the Mathews family farm, serving as a testament to the company’s willingness to push boundaries and experiment with bold ideas. This milestone highlights MC’s legacy of creativity and hands-on engineering excellence.

First Export Dryer

Mathews Company celebrated a historic achievement by shipping its first export-certified grain dryer overseas, officially launching its presence in global markets. Transported via American Airlines Freight, this dryer met rigorous international standards and opened the door for MC equipment to serve farmers far beyond North America. The milestone demonstrated MC’s commitment to quality, innovation, and a willingness to meet the needs of farmers worldwide. This pivotal export laid the foundation for decades of international partnerships and global growth.

First Canadian Dryer

Mathews Company achieved a major breakthrough by shipping its first grain dryer to Canada, marking the company’s official entry into international markets. This milestone demonstrated the growing reputation of MC’s dryers for quality and reliability beyond U.S. borders. Canadian farmers quickly recognized the value of MC’s innovative technology, which offered better grain drying efficiency and durability in harsh northern climates. The success of this first international sale paved the way for expanding MC’s footprint worldwide and supporting farmers across North America.

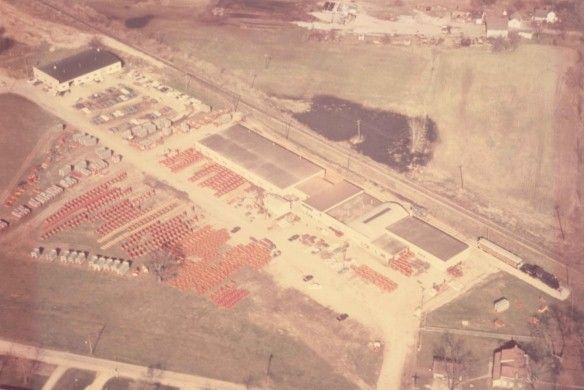

MC Moves Down the Road

As demand for Mathews Company’s innovative agricultural equipment surged, the company made a strategic move to a much larger facility at 500 Industrial Avenue in Crystal Lake. This new, expansive plant provided the space needed to scale up production and introduce new product lines, fueling MC’s rapid growth. The relocation also signaled MC’s evolution from a small shop to a major player in the industry, with room to invest in advanced manufacturing processes. This milestone marked a turning point, positioning MC to better serve farmers with high-quality equipment for decades to come.

Heavy Duty Mowers

MC expanded its product lineup with the launch of its first PTO-driven flail mowers, engineered to conquer the toughest mowing challenges farmers faced. Designed for durability and precision, these heavy-duty mowers delivered clean, consistent cuts even through dense weeds, brush, and uneven terrain. Their rugged construction and reliable performance quickly made them a favorite among farmers who needed equipment that could stand up to demanding conditions. This innovation solidified MC’s role as a trusted partner in helping farmers maintain their fields with ease and confidence.

MC Shredders Debut

Mathews Company unveiled its first 7-foot-wide Shredder, ushering in a new era of innovation for residue management on farms. Engineered for power and durability, these shredders allowed farmers to quickly and effectively break down stalks, corn stubble, and other crop residue, improving soil conditions for the next planting season. The MC Shredder’s rugged design and superior cutting performance set it apart from other equipment of the era. This groundbreaking product reinforced MC’s reputation for delivering tools that made farming more efficient and productive.

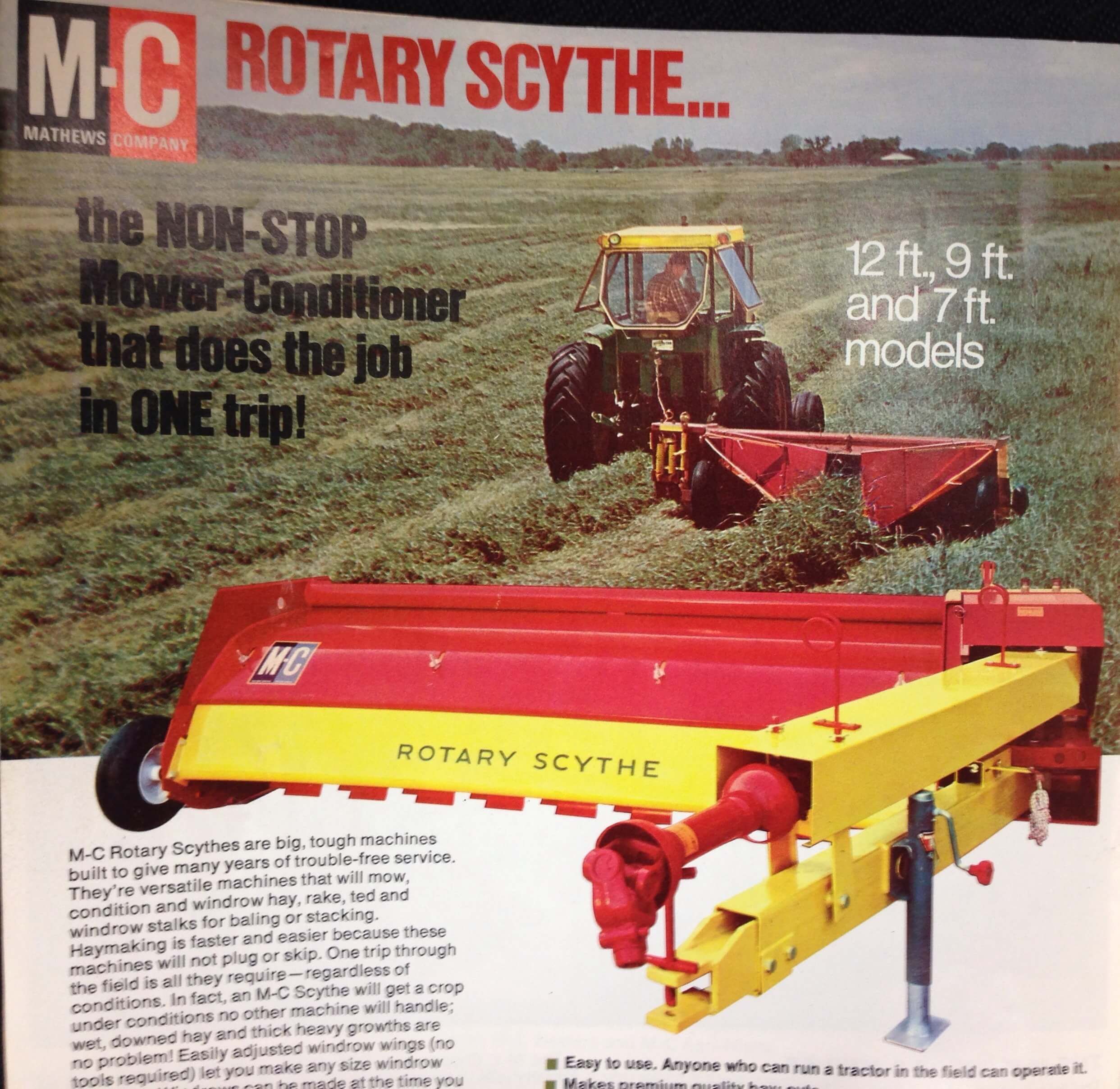

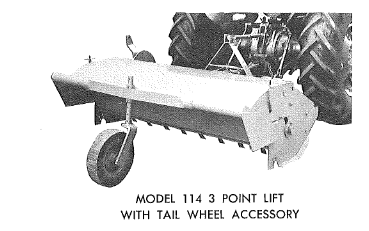

MC Rotary Scythes

Mathews Company introduced its line of nonstop rotary scythe mowers, offering 7-, 9-, and 12-foot models engineered for rugged, reliable performance in the field. These innovative machines combined mowing and conditioning in a single pass, dramatically improving efficiency for hay and forage operations. Farmers quickly embraced the MC Rotary Scythe’s ability to cut through thick crops without clogging, reducing downtime and increasing productivity. With bold design and dependable construction, these scythes became a symbol of MC’s dedication to helping farmers get more done with less effort.

Swing Knife Blitzers

Mathews Company introduced its groundbreaking Swing Knife Blitzers, featuring innovative free-swinging knife flails that revolutionized the way farmers managed tough vegetation. These powerful shredding mowers sliced through dense brush and crop residue with ease, saving time and reducing wear on equipment. By combining rugged durability with efficient cutting performance, the Swing Knife Blitzers quickly became a trusted tool for farmers seeking to maintain their fields and pastures. This innovation underscored MC’s commitment to creating solutions that made farming more productive and less labor-intensive.

First Grain Dryer Sold

Mathews Company reached a major milestone with the sale of its very first grain dryer in 1957. This groundbreaking sale signified the trust farmers were placing in MC’s innovative solutions and set the stage for nationwide growth. The early grain dryers, rugged and dependable, quickly proved their worth by helping farmers improve efficiency and crop quality. This pivotal moment ignited MC’s journey toward becoming a household name in grain drying equipment across the country.

MC Choppers

With the launch of its first mass-produced product, the MC Chopper, Mathews Company took a bold step toward becoming a leader in agricultural equipment. These innovative machines transformed the way farmers handled forage, offering a reliable, efficient solution that quickly gained popularity. The impressive sight of rows of freshly built choppers lined up outside the factory symbolized MC’s newfound production capabilities and ambition. This milestone laid the groundwork for future innovations and set the stage for decades of growth in serving the needs of hardworking farmers.

MC Sets Up Shop

Just two years after its founding, Mathews Company outgrew its humble garage and established its first official manufacturing facility at 301 Industrial Avenue in Crystal Lake, Illinois. This move marked a turning point, providing the space and infrastructure needed to meet growing demand for MC’s innovative equipment. The new facility became a hive of activity, with skilled craftsmen and engineers working side by side to deliver equipment that farmers could count on. It was here that MC began laying the foundation for a reputation built on quality, reliability, and a steadfast commitment to helping farmers succeed.