Bucket Elevators

1,300-13,500 BU/HR

18”, 24”, 30”, 36”, 42” PULLEYS

Our premium-grade bucket elevators feature high-quality construction utilizing fully welded and hot-dipped finishes, reliable components, and features to simplify construction on the job site.

| Model Number | Pulley Diameter | Bucket Size | Bucket Spacing | Trunk Size | Discharge Capacity | Spout Size |

| 18-75-075

18-75-065 |

18″ | 7″ x 5″ | 7.5″ 6.5″ |

11″ x 9″ | 1,300 bu/hr 1,600 bu/hr |

6″ |

| 24-106-105 24-106-085 24-106-075 |

24″ | 10″ x 6″ | 10.5″ 8.5″ 7.5″ |

14″ x 10″ | 2,500 bu/hr 3,100 bu/hr 3,600 bu/hr |

8″ |

| 30-117-100 30-117-085 |

30″ | 11″ x 7″ | 10″ 8.5″ |

15″ x 12″ | 4,900 bu/hr 5,700 bu/hr |

10″ |

| 36-147-095 36-147-085 |

36″ | 14″ x 7″ | 9.5″ 8.5″ |

18″ x 12″ | 7,300 bu/hr 8,200 bu/hr |

12″ |

| 42-148-095 42-188-095 |

42″ | 14″ x 8″ 18″ x 8″ |

9.5″ 9.5″ |

18″ x 14″ 22″ x 14″ |

10,400 bu/hr 13,500 bu/hr |

14″ 16″ |

Explore Features of our Bucket Elevators

Hover your cursor over the bubbles to learn more.

Bucket Elevators

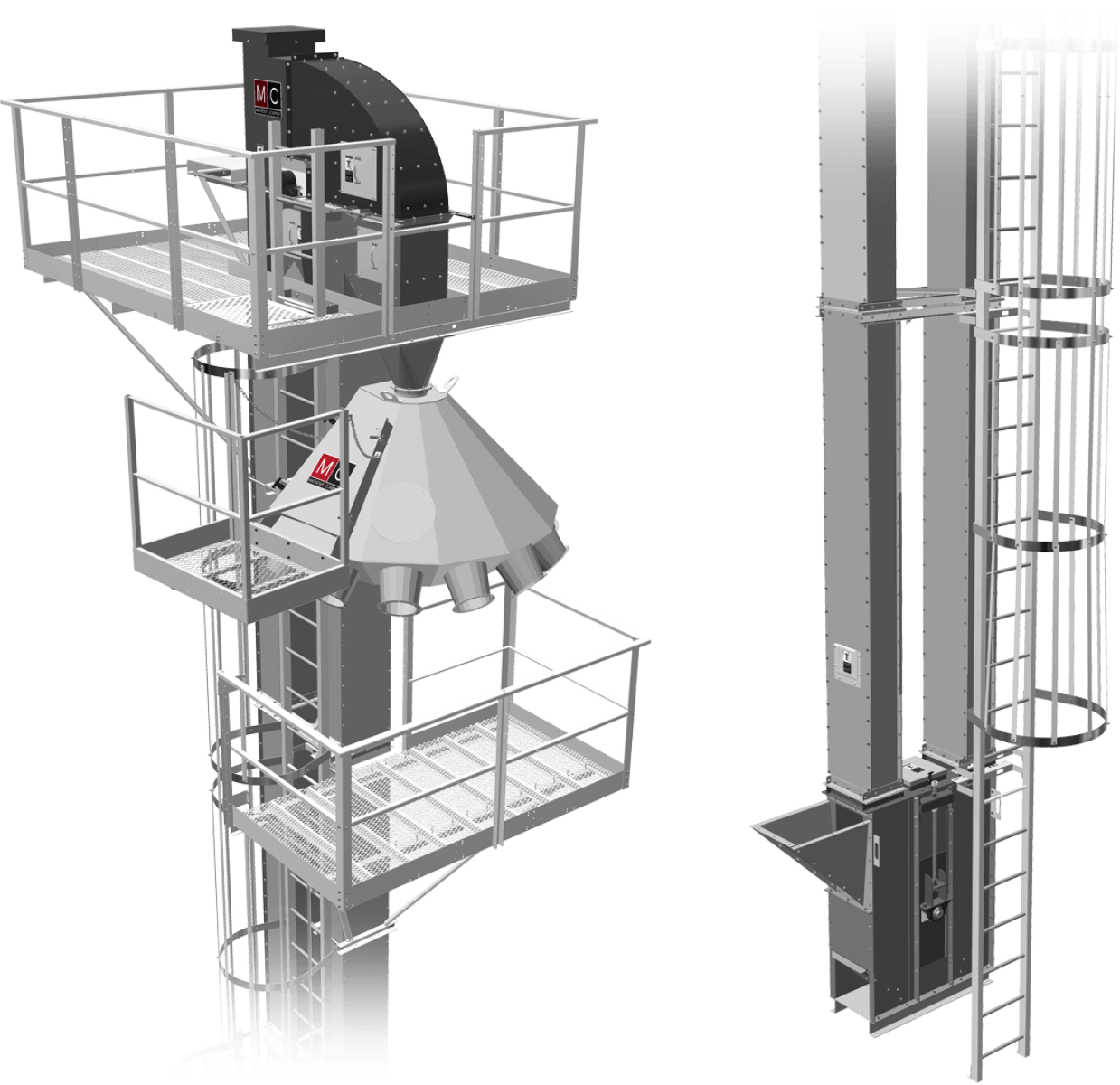

Head Service Platform

The optional head service platform provides safe and easy access to head section, motor, and drive components.

Distributor Platform

The optional distributor platform provides access to an optional distributor for ease of maintenance and adjustment.

Heavy-Duty Trunking

Laser-cut trunking is available in 14 ga or 11 ga galvanized steel, and features welded and hot-dipped galvanized flanges ensuring solid connection and precise alignment in the field.

Solid Head Section

Built to last with fully welded construction and hot-dipped galvanized finish.

Premium Drive

High quality construction utilizing Dodge TA-II gearbox reducers for heavy duty operation is standard.

Grain Distributor

Fully welded and hot-dipped galvanized grain distributor available in 6” – 16” diameter as 4-port, 6-port, or 8-port configuration.

Various Inlet Hoppers

To accommodate site-specific requirements, several configurations are available including single or dual inlets and different liner options.

Cage Winged Boot Pulley

Boot section pulley available in different styles including a winged design for quieter operation while minimizing excess material build up behind belt.

Inspection Sections

Configurable in 5′-0″ or 10′-0″ heights, base inspection sections are a standard feature providing access for maintenance.

Trunking Alignment

Ensuring a trouble-free installation, our trunking alignment system is specifically designed to stack true alleviating the need for shims and other costly adjustment work needed on the job site.

Modular Ladder & Cage

Numerous arrangements are available to include rest platforms needed to accommodate site conditions for safe and easy access.

Vented Head Section Cover

Using a vented head section cover, the hazards associated with excessive grain dust accumulation are reduced.